The integration of customer requirements and our requirements in project management

Release date:2025-01-09

In project management, the integration of customer requirements and company requirements is a very important part. If the integration cannot be effective, it will increase a lot of unnecessary workload (two sets of information). Let me introduce some of Masamura's practices.

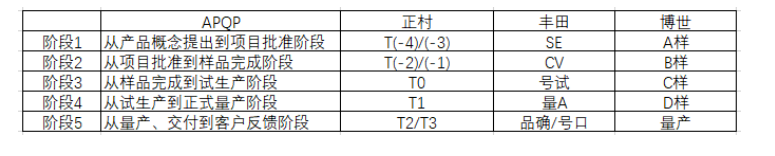

First, phase correspondence

In project management, the APQP manual divides the new product development process into five phases.

Through years of exploration and exploration, Ranzheng Village has formed distinctive project stages: T(-4), T(-3), T(-2), T(-1), T0, T1, T2, T3.

T(-4)/(-3) corresponds to the customer product design stage (Masamura designs products for customers or assists customers in joint design), and the end mark is the drawing lock.

T(-2)/(-1) corresponds to the mold design verification (Masamura's manufacturing feasibility assessment and verification of the product), and the end mark is locked for the mold drawing.

T0: OTS parts corresponding to customer mass production, end sign for customer approval of OTS sample.

T1: Corresponding to customer PPAP acknowledgement, end sign for customer approval of PSW.

T2: corresponding to the initial management and control stage of customers, the end mark is the pass rate and production capacity reach the standard.

T3: corresponding to our mass production stage

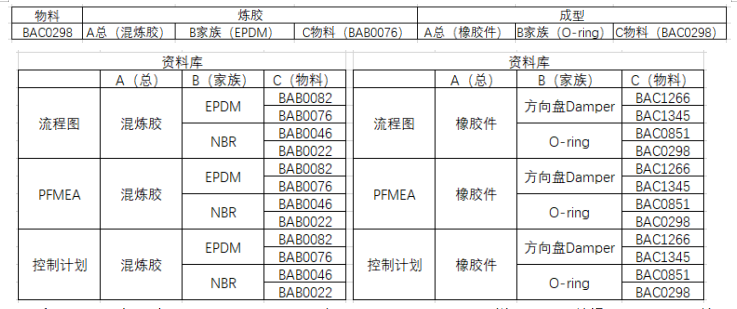

2. Data fusion

Masamura's customers include Japanese, American, European and private companies. Each customer product has different requirements, in order to meet the product requirements of different customer groups, Zhengcun data template design needs to integrate different requirements. Taking the process flow chart, PFMEA and control plan in the PPAP file as an example, usually, the development of a new project requires the preparation of a completed flow chart, PFMEA and control plan, which often takes more time and energy. By dividing the flow chart, PFMEA and control plan into three parts, A, B and C, Zhengcun solidifies A and B, and then realizes the matching of data with customer requirements by combining part C, thus reducing the repeated preparation of data in part A and B.

A is for maximum commonality - covers all products

B for product family commonality - covers family products

C is for maximum personality - individual product requirements

A, B and C do not contain each other

Taking the specific product BAC0298 as an example, the flow chart, PFMEA and control plan corresponding to the rubber and A+B+C in the molding are extracted from the database, which can quickly provide the three documents required by customers.

At this stage, all walks of life are Mired in "internal volume", how to combine customer requirements and company requirements without increasing costs is the wisdom of the management, Zhengcun will continue to explore and practice the road of integration.

Last article:Talk about the need for a return check

Next article:None